AEROSPACE

United Springs has many years of experience supplying the Aerospace Industry with Commercial/ Aircrafts and are Accredited to: ISO:9001/ AS:9100D.

United Springs has many years of experience supplying the Aerospace Industry with Commercial/ Aircrafts and are Accredited to: ISO:9001/ AS:9100D.

We are a successful global player in the automotive industry. We supply to the OEM as well as System suppliers.

The environment and ecology are at the heart of all concerns in the building industry.

Market in perpetual innovation to best meet consumers’needs and thus facilitate their daily lives with an increasingly widening product range.

Energy management has become a significant challenge for the coming years. We must do our best to save and preserve it, whether solar, wind, hydraulic, or other, we must do our best to save and preserve it.

The latter continues to evolve in search of gains in all areas (weight, assistance, new technology) while respecting the environment.

A wide range of our products; torsion-, compression-, leaf springs, wire forms, and assemblies, are used in many lighting applications of our customers.

Throughout the last century, we have cultivated partnerships with many industry leader to pioneer new technologies with applications as wide-ranging as power control, construction machinery, and safety equipment.

We supply all kinds of springs for different train sets and the railway.

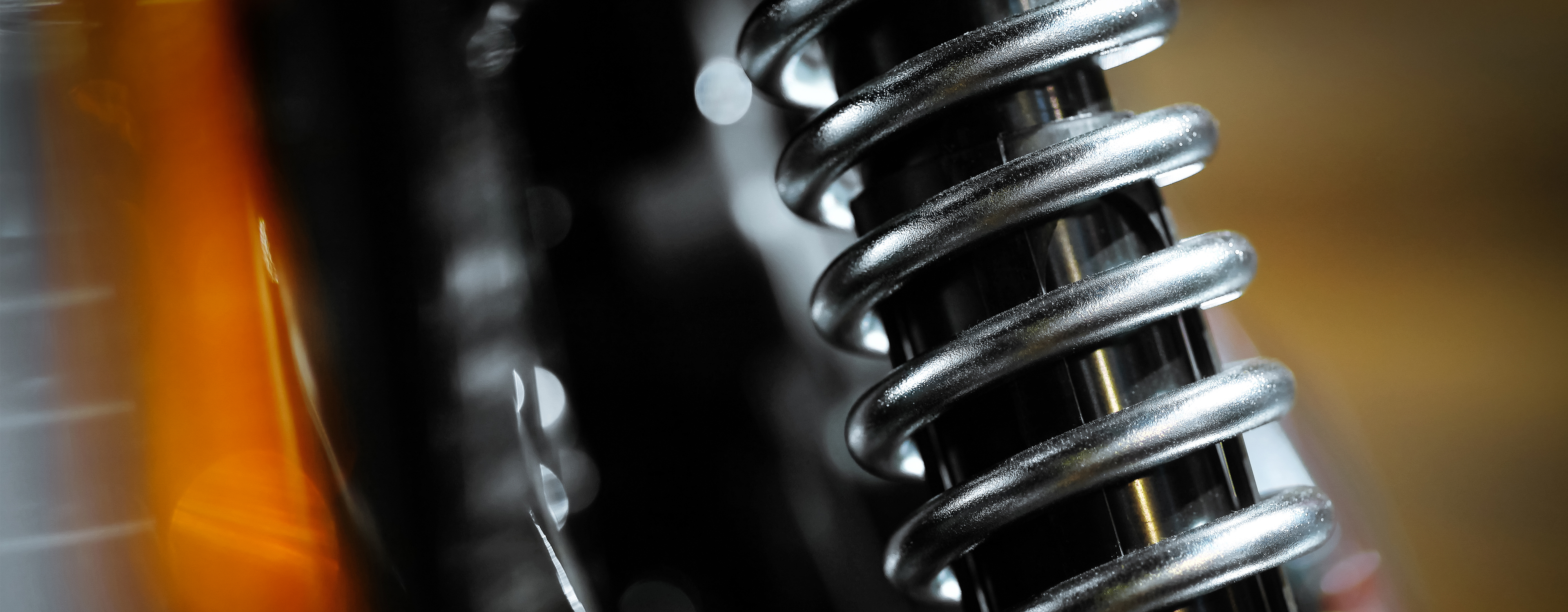

United Springs is a European leader in the development and manufacture of a wide and diverse range of springs comprising wire forms, flat, extension, torsion and compression springs for applications in a large number of industries.

United Springs is a European leader in the development and manufacture of a wide and diverse range of springs comprising wire forms, flat, extension, torsion and compression springs for applications in a large number of industries. Products are manufactured both with standard materials (carbon steel, stainless steel, oil-tempered steel and brass) and special materials (phosphor bronze, copper alloy, titanium, nimonic, inconel, elgiloy and several other exotic materials) according to specific customers’ needs.

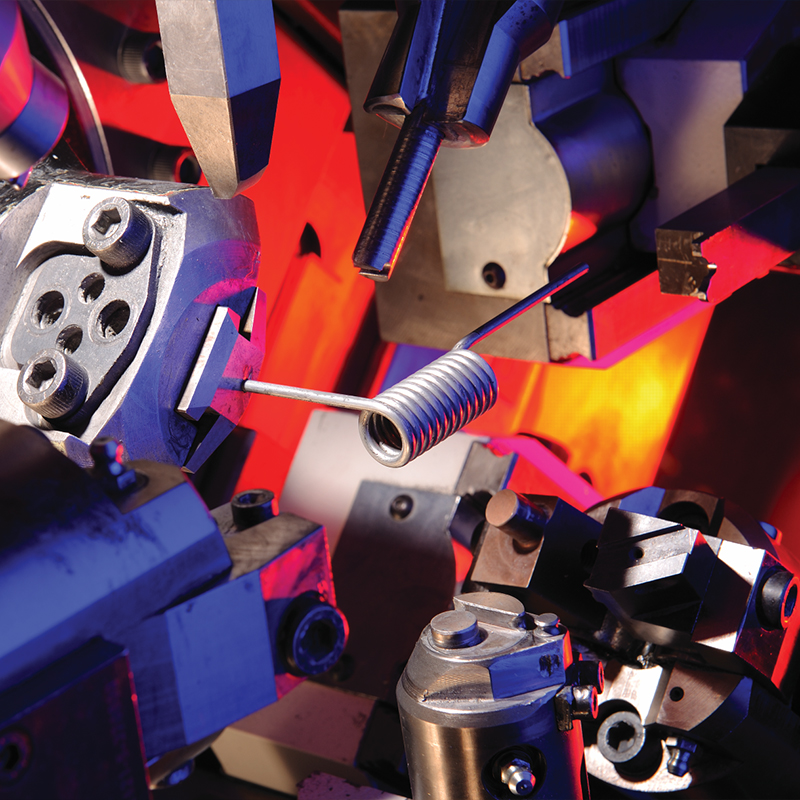

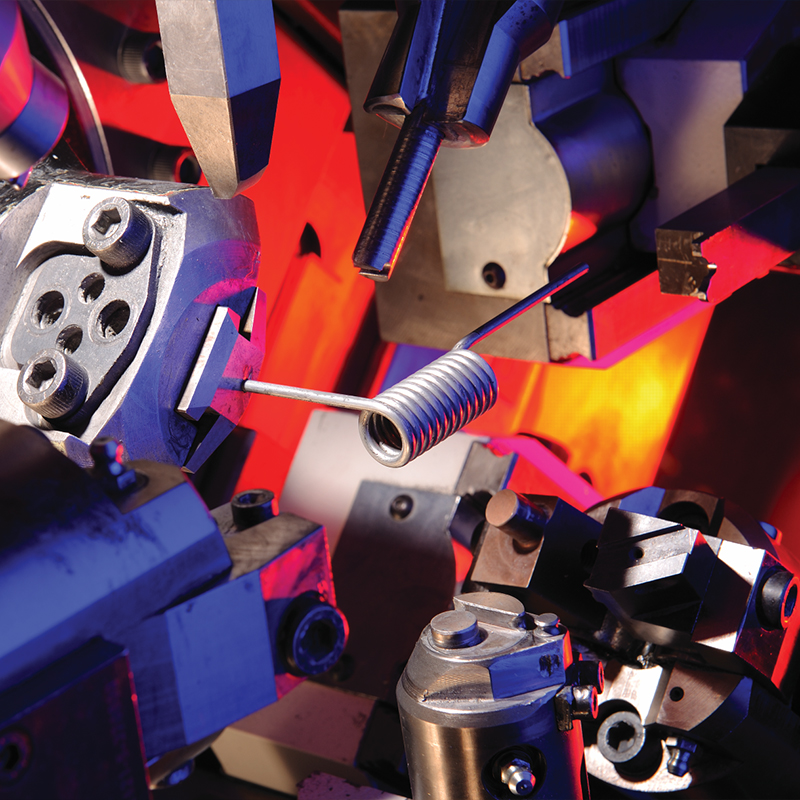

Wire forming is an art. We specialize in removing waste from the design and manufacturing processes.

Pressing is a process of strip forming a material in a stamping press or multi-slide bending tool (Bihler).

United Springs can assemble the spring to another springs, metal or plastic parts.

Quality is paramount in achieving our mission, to understand and exceed our customers’ expectations and to maintain world-class status in the design and manufacture of Springs, Wireforms, Pressings, and Assemblies.

Every part has to fulfill a specific function. Our skilled engineers are specialized to find the optimal solution for this.

To learn more about our springs and pressings for the automotive industry.

With manufacturing plants in France, The Netherlands, and the United Kingdom and sales offices in several countries, we are perfectly positioned to supply our global markets.